Dairy Fitting

Vinex Metal Industries is a leading Manufacturer and Exporter of high-quality Forged Fittings, located in Mumbai, India. We specialize in producing precision-forged pipe fittings using premium-grade raw materials, carefully inspected by our skilled professionals to ensure exceptional strength, integrity, and performance.

Each of our Forged Fittings is manufactured in strict compliance with National and International Standards, ensuring our clients receive durable, high-performing components for a wide range of industrial applications. Our commitment to quality and reliability has made us a trusted partner to industries worldwide.

Vinex Metal Industries offers a comprehensive range of forged fittings, crafted using the finest raw materials. These fittings are subjected to stringent quality checks and performance tests to ensure they meet the rigorous demands of high-pressure and high-temperature systems.

Our forged fittings are available in a variety of types, sizes, and grades, including Stainless Steel, Carbon Steel, Duplex Steel, Super Duplex Steel, Alloy Steel, Nickel Alloy, Titanium Alloy, and Copper Nickel Alloy. Known for their corrosion resistance, dimensional precision, and long-lasting durability, these fittings are ideal for critical industrial operations.

Supported by a team of experienced professionals and equipped with state-of-the-art manufacturing facilities, Vinex Metal Industries is dedicated to delivering world-class forged fittings that meet the highest standards of engineering excellence and customer satisfaction in global markets.

Available Grades of Dairy Fitting

| Material | Available Grades | Common Applications |

|---|---|---|

| Stainless Steel | 304, 304L, 316, 316L | Food processing, dairy, beverage, and pharmaceutical industries |

| Duplex Steel | UNS S31803, UNS S32205 | High-strength and corrosion-resistant applications, especially in CIP/SIP lines |

| Super Duplex Steel | UNS S32750, UNS S32760 | Aggressive chemical environments or high-pressure hygienic systems |

| Nickel Alloys | Alloy 200, Alloy 400, Inconel 600/625 | Specialty fittings for high corrosion resistance or temperature resistance |

| Titanium | Grade 2, Grade 5 | Pharmaceutical and biotech applications where biocompatibility is essential |

Dimensional Standards of Dairy Fittings

| Fitting Type | Size (Inch / DN) | Outer Diameter (OD) (mm) | Length / Center-to-End (mm) | Wall Thickness (mm) | Standard |

|---|---|---|---|---|---|

| 90° Bend | 1" | 25.4 | 38 | 1.5 | DIN 11852 / ISO |

| 90° Bend | 2" | 50.8 | 57 | 1.5 | DIN 11852 / ISO |

| Dairy Tee | 1" | 25.4 | 76 x 38 | 1.5 | DIN 11852 |

| Dairy Tee | 2" | 50.8 | 102 x 57 | 1.5 | DIN 11852 |

| 180° Bend | 1" | 25.4 | 76 | 1.5 | DIN / ISO |

| 180° Bend | 2" | 50.8 | 152 | 1.5 | DIN / ISO |

| Tri-Clamp | 1" | 50.5 | 15 (width) | - | ISO 2852 |

| Tri-Clamp | 2" | 64 | 18 (width) | - | ISO 2852 |

| Dairy Ferrule | 1" | 50.5 | 12.7 | 1.5 | SMS / DIN / ISO |

| Dairy Ferrule | 2" | 64 | 21.5 | 1.5 | SMS / DIN / ISO |

| Sight Glass | 1" | 50.5 | 100 | 3 (Glass Thickness) | 3A / DIN |

| Sight Glass | 2" | 64 | 150 | 3 (Glass Thickness) | 3A / DIN |

| Ball Valve | 1" | 25.4 | 120 | 1.5 | 3A / SMS |

| Butterfly Valve | 2" | 50.8 | 140 | 1.5 | 3A / SMS |

| Sampling Valve | 1" | 25.4 | 95 | 1.5 | DIN / 3A |

Types of Dairy Fitting

Dairy Fitting Elbow

A Dairy Fitting Elbow is a hygienic pipe fitting designed to redirect flow at 90° or 45° angles in sanitary process lines. Manufactured to meet stringent food-grade and pharmaceutical standards, these elbows ensure smooth, crevice-free flow with minimal pressure drop. They are typically fabricated using stainless steel and are available in butt weld, tri-clamp, and SMS/DIN connections, making them ideal for clean-in-place (CIP) and sterilize-in-place (SIP) systems.

Key Features

- Available in 90° and 45° angles to redirect flow in hygienic pipelines.

- Designed with Butt Weld, Tri-Clamp, SMS, or DIN end connections.

- Fabricated using food-grade Stainless Steel (typically SS 304 / SS 316L).

- Highly polished internal surface to reduce contamination risk and ensure easy cleaning.

- Ideal for applications in dairy, beverage, food processing, brewery, and pharmaceutical industries.

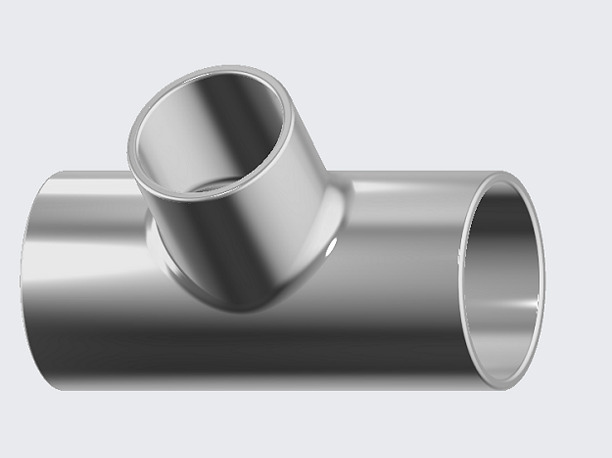

Dairy Fitting Tee

A Dairy Tee is a hygienic pipe fitting used to split or merge fluid flow in processing pipelines. It is available in Equal Tee and Reducing Tee configurations and is manufactured with a smooth, polished internal surface to maintain sanitary conditions. Designed for easy cleaning and minimal fluid retention, dairy tees are commonly used in food, dairy, brewery, beverage, and pharmaceutical applications requiring high levels of cleanliness and efficiency.

Key Features

- Available in Equal Tee and Reducing Tee configurations.

- End connections include Butt Weld, Tri-Clamp, SMS, and DIN standards.

- Manufactured from food-grade Stainless Steel (SS 304 / SS 316L).

- Mirror-polished internal surface for maximum hygiene and easy cleaning.

- Ideal for fluid distribution in dairy, food processing, beverage, and pharmaceutical systems.

Dairy Fitting Bend

A Dairy Bend is a hygienic pipe fitting used to change the direction of fluid flow smoothly in process piping systems. These bends are designed with a large radius and polished internal surfaces to minimize turbulence, prevent fluid stagnation, and allow easy cleaning. Commonly available in 45°, 90°, and 180° angles, they are essential components in sanitary pipelines within the dairy, food, beverage, and pharmaceutical industries.

Key Features

- Available in 45°, 90°, and 180° angles for flexible pipeline layouts.

- Smooth interior finish to reduce pressure loss and support clean-in-place (CIP) processes.

- End connections include Tri-Clamp, Butt Weld, SMS, DIN, and RJT standards.

- Manufactured from high-grade SS 304 / SS 316L for superior corrosion resistance and hygiene.

- Used in dairy, food, brewery, cosmetics, and pharmaceutical piping systems.

Tri-Clamp

The Tri-Clamp, also known as a sanitary clamp or hygienic clamp, is a quick-release pipe coupling used to securely connect sanitary process lines. It provides a tight, leak-proof seal between fittings, gaskets, and ferrules, making it ideal for systems that require frequent cleaning or maintenance. Tri-Clamps are widely used in the food, dairy, beverage, and pharmaceutical industries due to their ease of use, cleanliness, and durability.

Key Features

- Quick-release coupling system for easy assembly and disassembly of pipelines.

- Ensures a tight and hygienic seal when used with compatible ferrules and gaskets.

- Available in various sizes, compatible with SMS, DIN, 3A, and ISO standards.

- Made from high-grade stainless steel (SS 304 / SS 316L) for sanitary environments.

- Ideal for CIP (Clean-in-Place) and SIP (Steam-in-Place) applications.

Ferrule

A Ferrule is a precision-machined component used in sanitary pipe connections to provide a smooth, crevice-free transition between fittings. It is typically welded to pipes or equipment and used in combination with Tri-Clamps and gaskets to create a secure and hygienic connection. Dairy ferrules are critical in systems that demand frequent cleaning and contamination control, such as in dairy, food processing, beverage, and pharmaceutical industries.

Key Features

- Provides a clean, hygienic weld end for Tri-Clamp and other sanitary connections.

- Designed with smooth inner surfaces to prevent bacterial growth and contamination.

- Manufactured to meet 3A, DIN, SMS, and ISO hygienic standards.

- Available in long weld and short weld types, depending on installation needs.

- Constructed from stainless steel (SS 304 / SS 316L) for superior corrosion resistance and durability.

Valve (Ball, Butterfly, Sampling)

Valves in dairy fittings play a critical role in controlling the flow of liquids and gases in piping systems. Available in types like Ball, Butterfly, and Sampling, these valves ensure precision, hygiene, and easy operation. They are essential components for sanitary pipelines in the dairy, food & beverage, and pharmaceutical industries. These valves help to control flow rates, isolate parts of the system, and facilitate easy sampling of the contents in pipelines.

Key Features

- Ball Valve: Offers excellent sealing performance, ensuring tight shut-off with minimal leakage. Ideal for on/off control in pipelines.

- Butterfly Valve: Compact, lightweight, and ideal for controlling the flow of fluids in large diameter pipelines. Offers quick operation and low pressure drop.

- Sampling Valve: Used for collecting fluid samples without disrupting the pipeline system. Provides hygienic, clean, and efficient sampling for quality control.

- All valve types are made of high-quality materials like Stainless Steel, designed to meet stringent sanitary and hygiene standards.

- Available in a range of sizes and pressure ratings to suit different dairy, food & beverage, and pharmaceutical applications.

Applications of Dairy Fittings

Dairy fittings are essential components in hygienic and sanitary processing systems where cleanliness, contamination control, and corrosion resistance are critical. These fittings are widely used in industries that require sterile and easy-to-clean piping systems. Some of the key applications include:

- Dairy Processing: Used in milk processing plants for the transportation of milk, cream, whey, and other dairy products under sanitary conditions.

- Food & Beverage Industry: Applied in the processing of juices, sauces, beverages, and other food products requiring hygienic piping systems.

- Pharmaceutical Industry: Ensures sterile and contamination-free flow of liquid medicines, solutions, and other pharmaceutical substances.

- Biotechnology & Life Sciences: Used in bioprocessing systems for handling sensitive and sterile fluids during research and production.

- Brewery & Distillery: Integral in breweries for the clean transport of beer, wine, and spirits during fermentation, filtering, and packaging stages.

- Cosmetics & Personal Care: Used for transporting creams, gels, and liquid products where purity and cleanability are critical.

- Water Purification Systems: Applied in systems requiring high-purity water transport without contamination or corrosion.

- Chemical & Fermentation Industries: Used in non-toxic and food-safe chemical processing and fermentation pipelines.