Flanges

Vinex Metal Industries is a leading Manufacturer and Exporter of high-quality Flanges, located in Mumbai, India. We specialize in manufacturing precision-engineered Flanges using the finest raw materials, rigorously tested and controlled by our skilled professionals to ensure unparalleled performance and durability.

Each of our Flanges is made in strict accordance with both National and International Industrial Standards, ensuring that our customers receive products that are not only reliable but also long-lasting. Our commitment to quality and excellence has made us a trusted supplier to a wide range of industries across the globe.

Vinex Metal Industries is a trusted manufacturer and exporter of a diverse range of flanges. Crafted from premium-quality raw materials, our flanges undergo stringent quality control and rigorous testing to ensure superior durability and performance. Each flange is manufactured in compliance with national and international industrial standards, guaranteeing reliability across various applications.

We offer flanges in multiple types and grades, including Stainless Steel, Carbon Steel, Duplex Steel, Super Duplex Steel, Alloy Steel, Nickel Alloy, Titanium Alloy, and Cupro-Nickel Alloy. With the expertise of our skilled professionals, we provide high-quality flanges known for their strength, precision, and long-lasting performance.

Our experienced engineers leverage advanced manufacturing techniques and top-grade materials to produce flanges that meet industry standards and customer specifications. At Vinex Metal Industries, we are dedicated to delivering top-tier flanges that cater to the diverse needs of industries worldwide.

Available Grades of Flanges

| Material Type | Standards | Available Grades | |

|---|---|---|---|

| ASTM | ASME | ||

| Stainless Steel | A182 | A240 | F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H, 904L |

| - | - | ||

| Carbon Steel | A105 | A350 | LF2, A516 Gr.70, A36, A694 F42, F46, F52, F60, F65, F70 |

| A181 | - | LF2 | |

| Alloy Steel | A182 | A387 | F1, F5, F9, F11, F12, F22, F91 |

| Duplex Steel | A182 | - | F44, F45, F51, F53, F55, F60, F61 |

| Super Duplex Steel | A182, A240 | - | F44, F45, F51, F53, F55, F60, F61 |

| Nickel Alloy | - | Nickel 200, Nickel 201, Monel 400, Monel 500, Inconel 800, Inconel 825, Inconel 600, Inconel 625, Inconel 601, Hastelloy C 276, Alloy 20, Titanium (Grade I & II) | |

| Copper Alloy | - | UNS No. C10100, 10200, 10300, 10800, 12000, 12200, 70600, 71500, C 70600 (Cu-Ni-90/10), C 71500 (Cu-Ni-70/30) | |

| Low Temperature Carbon Steel | A350 | - | LF2, LF3 |

Dimensional Standards of Flanges

Types of Flanges

Slip - On Flange

Slip-On Flanges are widely used for low-pressure applications and provide an easy, cost-effective solution for pipe connections. These flanges are designed to slip over the pipe before being welded in place, ensuring secure and leak-proof connections. They are available in various materials and pressure ratings, making them suitable for industries such as oil & gas, petrochemicals, water treatment, power plants, and general piping systems.

Key Features

- Designed to slip over the pipe and welded for a secure, leak-proof connection.

- Available in various materials, including stainless steel, carbon steel, alloy steel, and exotic alloys.

- Suitable for low to moderate pressure applications.

- Available in different pressure ratings, including 150#, 300#, 600#, and higher as per industry requirements.

- Widely used in industries such as oil & gas, petrochemicals, water treatment, power plants, and general piping systems.

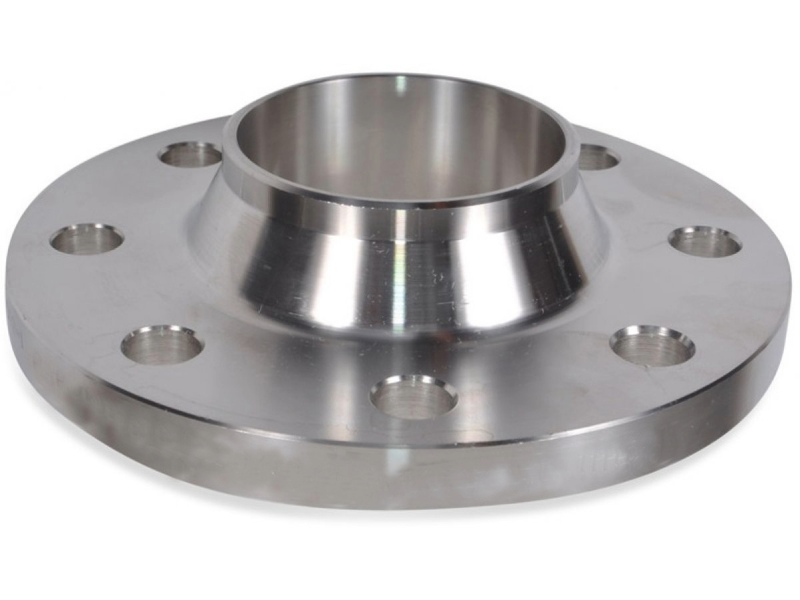

Welding Neck Flange

Welding Neck Flanges are designed for high-pressure and high-temperature applications, offering superior strength and durability. These flanges have a long tapered hub that provides excellent reinforcement to the piping system, reducing stress concentrations at the flange connections. They are commonly used in critical industries such as oil & gas, petrochemicals, power plants, and shipbuilding, where reliability and leak-proof performance are essential.

Key Features

- Designed with a long tapered hub that provides reinforcement and reduces stress concentration

- Ideal for high-pressure and high-temperature applications

- Available in various materials, including stainless steel, carbon steel, alloy steel, and nickel alloys

- Manufactured in different pressure ratings, including 150#, 300#, 600#, 900#, 1500#, and 2500#

- Commonly used in industries such as oil & gas, petrochemicals, power plants, shipbuilding, and process industries

Blind Flange

Blind Flanges are solid disk-shaped flanges designed to close the end of a piping system or pressure vessel openings. These flanges provide a reliable solution for isolating a pipeline, facilitating maintenance, and pressure testing. With no center bore, Blind Flanges ensure zero leakage, making them ideal for high-pressure and high-temperature applications across industries such as oil & gas, petrochemicals, power plants, and water treatment.

Key Features

- Solid, flat-faced flange designed to close the end of pipelines and pressure vessels

- Provides a secure and leak-proof seal, preventing flow and allowing for system maintenance

- Available in various materials, including stainless steel, carbon steel, alloy steel, and nickel alloys

- Manufactured in multiple pressure ratings, including 150#, 300#, 600#, 900#, 1500#, and 2500#

- Commonly used in industries such as oil & gas, petrochemicals, power plants, water treatment, and chemical processing

Socket Weld Flange

Socket Weld Flanges are designed for small-diameter, high-pressure piping systems, ensuring strong and durable connections. These flanges feature a socket-like bore where the pipe is inserted before being welded, providing excellent strength and fatigue resistance. Socket Weld Flanges are commonly used in industries such as oil & gas, petrochemicals, power plants, and chemical processing, where high-performance sealing and structural integrity are essential.

Key Features

- Features a socket-like bore where the pipe is inserted before being welded for a strong connection

- Provides excellent fatigue resistance, making it ideal for high-pressure applications

- Available in various materials, including stainless steel, carbon steel, alloy steel, and exotic alloys

- Manufactured in multiple pressure ratings, including 150#, 300#, 600#, 900#, 1500#, and 2500#

- Commonly used in oil & gas, petrochemical, power generation, and chemical processing industries

Threaded Flange

Threaded Flanges, also known as screwed flanges, are designed for easy installation without the need for welding. These flanges have an internal thread that allows them to be screwed onto a matching pipe, making them ideal for low-pressure and non-critical applications. They are commonly used in industries such as plumbing, water supply, gas processing, and small-diameter piping systems where welding is impractical or not permitted.

Key Features

- Features an internally threaded bore that allows for easy installation without welding

- Ideal for low-pressure and non-critical applications where welding is impractical

- Available in various materials, including stainless steel, carbon steel, alloy steel, and brass

- Manufactured in standard pressure ratings such as 150#, 300#, 600#, and higher as required

- Commonly used in plumbing, water supply, gas distribution, and chemical processing applications

Long Weld Neck Flange

Long Weld Neck Flanges are specially designed for high-pressure and high-temperature applications, offering enhanced structural reinforcement. These flanges feature an extended neck that provides additional support to the piping system, reducing stress concentrations and improving durability. Long Weld Neck Flanges are commonly used in pressure vessels, heat exchangers, refineries, and chemical processing industries where strength and reliability are crucial.

Key Features

- Extended neck design provides superior reinforcement and reduces stress concentrations

- Ideal for high-pressure and high-temperature applications requiring robust connections

- Available in stainless steel, carbon steel, alloy steel, and special-grade materials

- Manufactured in pressure ratings such as 150#, 300#, 600#, 900#, 1500#, and 2500#

- Commonly used in pressure vessels, heat exchangers, refineries, and petrochemical industries

Ring Type Joint Flange

Ring Type Joint (RTJ) Flanges are designed for high-pressure and high-temperature applications, ensuring a leak-proof and secure connection. These flanges feature a precision-machined groove where a metal ring gasket is seated, providing superior sealing performance. RTJ Flanges are commonly used in critical industries such as oil & gas, petrochemical, refineries, and offshore drilling, where extreme conditions demand reliable and durable connections.

Key Features

- Extended neck design provides superior reinforcement and reduces stress concentrations

- Ideal for high-pressure and high-temperature applications requiring robust connections

- Available in stainless steel, carbon steel, alloy steel, and special-grade materials

- Manufactured in pressure ratings such as 150#, 300#, 600#, 900#, 1500#, and 2500#

- Commonly used in pressure vessels, heat exchangers, refineries, and petrochemical industries

Applications of Flanges

Flanges are crucial components in various industries due to their ability to connect pipes, valves, pumps, and other equipment efficiently while ensuring secure and leak-proof connections. Some of the key applications include:

- Oil & Gas Industry: Used in pipeline connections, refineries, and offshore drilling platforms for secure fluid transfer.

- Petrochemical & Refineries: Essential in high-temperature and high-pressure environments for chemical processing.

- Power Plants: Widely used in thermal, nuclear, and hydroelectric plants for steam and fluid transmission systems.

- Water Treatment Plants: Used in desalination and purification plants to ensure secure and corrosion-resistant connections.

- Pharmaceutical Industry: Enables leak-proof and contamination-free connections in fluid handling systems.

- Food & Beverage Industry: Stainless steel flanges are preferred for their hygienic and corrosion-resistant properties in food processing.

- Shipbuilding & Marine: Used in seawater pipelines, ballast systems, and offshore drilling platforms for secure piping.

- Construction & Infrastructure: Essential for plumbing systems, water supply networks, and structural piping in buildings and infrastructure projects.