Sheet & Plate

Vinex Metal Industries is a trusted Manufacturer and Exporter of high-quality Sheets and Plates, engineered for critical applications across diverse industries. Based in Mumbai, India, we specialize in precision-rolled flat products that ensure superior strength, surface finish, and performance under extreme operating conditions.

Our extensive range of Sheets and Plates is available in a variety of grades, sizes, thicknesses, and finishes, manufactured in accordance with international standards such as ASTM, ASME, and API. Whether you require hot rolled, cold rolled, or custom-fabricated solutions, we deliver metal products that meet stringent quality and dimensional accuracy standards.

We use only premium raw materials including Stainless Steel, Carbon Steel, Alloy Steel, Duplex & Super Duplex, Nickel Alloys, Titanium, and Cupro-Nickel, ensuring that each product offers excellent mechanical properties, corrosion resistance, and durability. All sheets and plates undergo thorough quality checks and non-destructive testing (NDT) to meet global performance expectations.

Widely used in sectors such as Oil & Gas, Petrochemical, Power Generation, Automotive, Aerospace, Construction, Marine, and Heavy Engineering, our sheet and plate solutions are suitable for applications involving fabrication, structural reinforcement, pressure vessels, and heat exchangers.

At Vinex Metal Industries, we also offer customized sheet and plate solutions with flexible options in length, width, thickness, and surface treatments (No.1, 2B, BA, Mirror, Matte, Brushed). Our commitment to engineering precision, timely delivery, and customer satisfaction makes us a preferred choice for metal sheet and plate requirements worldwide.

Available Grades of Sheet & Plate

| Material | Standard | Available Grades | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | ||

| Stainless Steel | ASTM A312 / A213 | 304 | 304L | 304H | 309 | 310 | 310S | 316 | 316L | 316Ti | 317L |

| 321 | 321H | 347 | 347H | 410 | 446 | 904L | |||||

| Duplex / Super Duplex | ASTM A790 / A928 | Duplex S31803 / S32205 | Super Duplex S32750 / S32760 | ||||||||

| Nickel Alloys | ASTM B161 / B163 | Nickel 200 | Nickel 201 | Inconel 600 | Inconel 601 | Inconel 625 | Inconel 718 | Incoloy 800 | Incoloy 800HT | Incoloy 825 | |

| Alloy Steel | ASTM A335 / A213 | P5 | P9 | P11 | P12 | P22 | P91 | P92 | |||

| Titanium | ASTM B338 | Gr 1 | Gr 2 | Gr 5 | Gr 9 | ||||||

| Carbon Steel | ASTM A106 / A53 / API 5L | Seamless | ERW | SAW | LSAW | HSAW | API 5L | ||||

| Copper Nickel | ASTM B466 / B467 | CuNi 70/30 | CuNi 90/10 | ||||||||

| Other Alloys | - | SMO 254 | Alloy 28 | 253 MA (S30815) | Alloy 20 | Hastelloy | Aluminium | ||||

Dimensional Standards of Sheet & Plate

| Sheet Type | Dimensions (mm) | Thickness Range | Standard | |

|---|---|---|---|---|

| Width (W) | Length (L) | |||

| Sheets | 1000 | 2000 | 0.5mm - 50mm | ASTM A240 / A480 |

| 1220 | 2440 | 0.5mm - 50mm | ||

| 1500 | 3000 | 0.5mm - 50mm | ||

| Plates | 1000 | 2500 | 3mm - 100mm | ASTM A240 / A480 |

| 1250 | 5000 | 3mm - 100mm | ||

| 2000 | 6000 | 3mm - 100mm | ||

| Coils | 1000 | Custom Length | 0.3mm - 6mm | ASTM A240 / A480 |

| 1250 | Custom Length | 0.3mm - 6mm | ||

| 1500 | Custom Length | 0.3mm - 6mm | ||

Types of Sheets & Plates

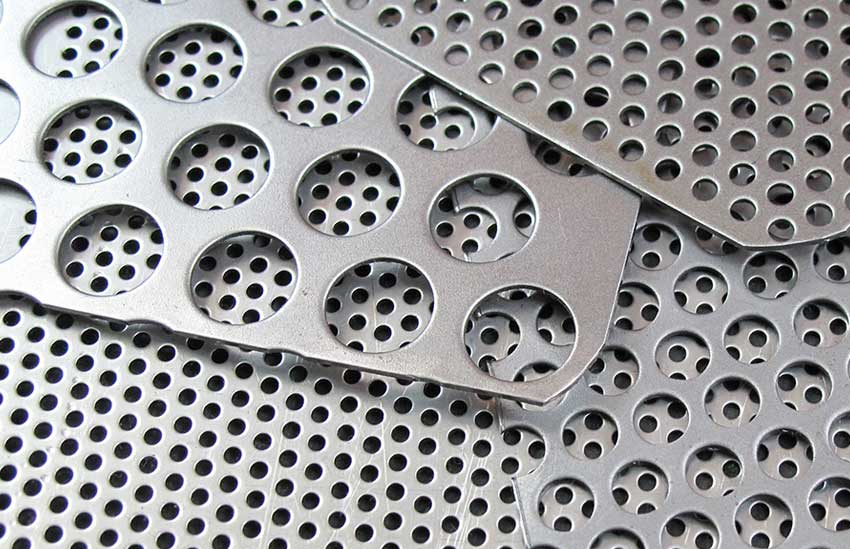

Perforated Sheets

Perforated sheets are metal sheets that have been manually or mechanically stamped or punched to create a pattern of holes, slots, or decorative shapes. These sheets offer excellent ventilation, aesthetic appeal, and functionality across various applications such as architectural design, filtration, acoustic control, and industrial screening. Available in different materials including stainless steel, aluminum, and mild steel, perforated sheets provide a balance between strength, lightness, and open area.

Key Features

- Customizable hole sizes, shapes, and open area percentages.

- Provides effective airflow, light filtration, and acoustic performance.

- Manufactured in stainless steel, aluminum, mild steel, and other alloys.

- Corrosion-resistant and suitable for both indoor and outdoor use.

- Widely used in architecture, HVAC systems, machinery guards, and filtration units.

Chequered Plates

Chequered plates, also known as tread plates or diamond plates, are metal plates with a regular pattern of raised diamonds or lines on one side. These textured surfaces offer enhanced grip and anti-slip properties, making them ideal for flooring, ramps, stair treads, industrial walkways, and transport platforms. Manufactured from materials such as carbon steel, stainless steel, and aluminum, chequered plates combine strength, durability, and aesthetic appeal for heavy-duty and safety-critical environments.

Key Features

- Raised patterns provide excellent slip resistance for safe footing.

- Durable and wear-resistant surface ideal for industrial and outdoor applications.

- Available in materials like carbon steel, stainless steel, and aluminum.

- Easy to fabricate, cut, and install on structural surfaces.

- Widely used in platforms, stairways, catwalks, truck beds, and ship decks.

Shim Sheets

Shim sheets are precision-thin metal sheets used for accurate spacing, alignment, and calibration in critical assemblies. These sheets are widely used in aerospace, automotive, marine, electronics, and tooling industries where minimal tolerances and exact thickness control are required. Shim sheets are available in a variety of materials including stainless steel, brass, copper, aluminum, and carbon steel, and come in various hardness levels, finishes, and thicknesses as per application requirements.

Key Features

- Precision thickness control for critical alignment and tolerance applications.

- Available in stainless steel, copper, brass, aluminum, and other alloys.

- Offered in both soft annealed and hardened tempers as required.

- Excellent corrosion resistance and stability in demanding environments.

- Commonly used in aerospace, tooling, machinery, electronics, and valve shimming.

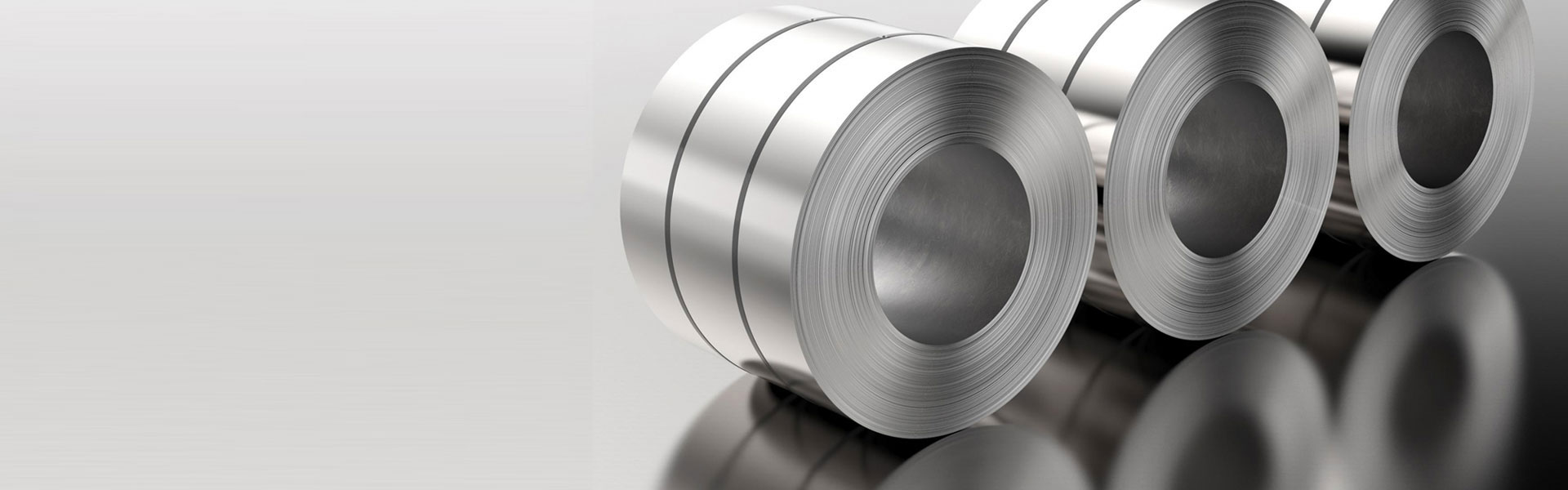

Coils

Metal coils are continuous lengths of sheet or strip material wound into rolls, used extensively in fabrication, stamping, forming, and manufacturing processes. Coils are available in hot rolled, cold rolled, galvanized, and color-coated variants across a wide range of materials including stainless steel, carbon steel, alloy steel, aluminum, copper, and nickel alloys. These coils are widely used in automotive, construction, electrical, HVAC, and appliance manufacturing for their versatility, durability, and formability.

Key Features

- Supplied in continuous roll form for efficient cutting, slitting, and forming.

- Available in hot rolled, cold rolled, galvanized, and color-coated finishes.

- Manufactured in stainless steel, carbon steel, aluminum, and alloy grades.

- Excellent surface finish, dimensional tolerance, and mechanical properties.

- Used in automotive panels, roofing, appliances, pipelines, and structural components.

Strips

Metal strips are narrow, precision-cut flat metal products, supplied in coil or straight form for various manufacturing and fabrication purposes. These strips offer exceptional dimensional accuracy and surface finish, making them ideal for applications in electronics, automotive, construction, stamping, and metal forming. Available in a range of materials like stainless steel, carbon steel, aluminum, and copper alloys, metal strips are offered in different thicknesses, tempers, and surface finishes to meet critical application needs.

Key Features

- Supplied in narrow widths with precise dimensional tolerances.

- Excellent surface finish for stamping, forming, and deep drawing.

- Available in stainless steel, aluminum, copper, carbon steel, and other alloys.

- Offered in cold-rolled, annealed, pickled, or polished conditions.

- Used in automotive parts, electrical components, washers, brackets, and precision tools.

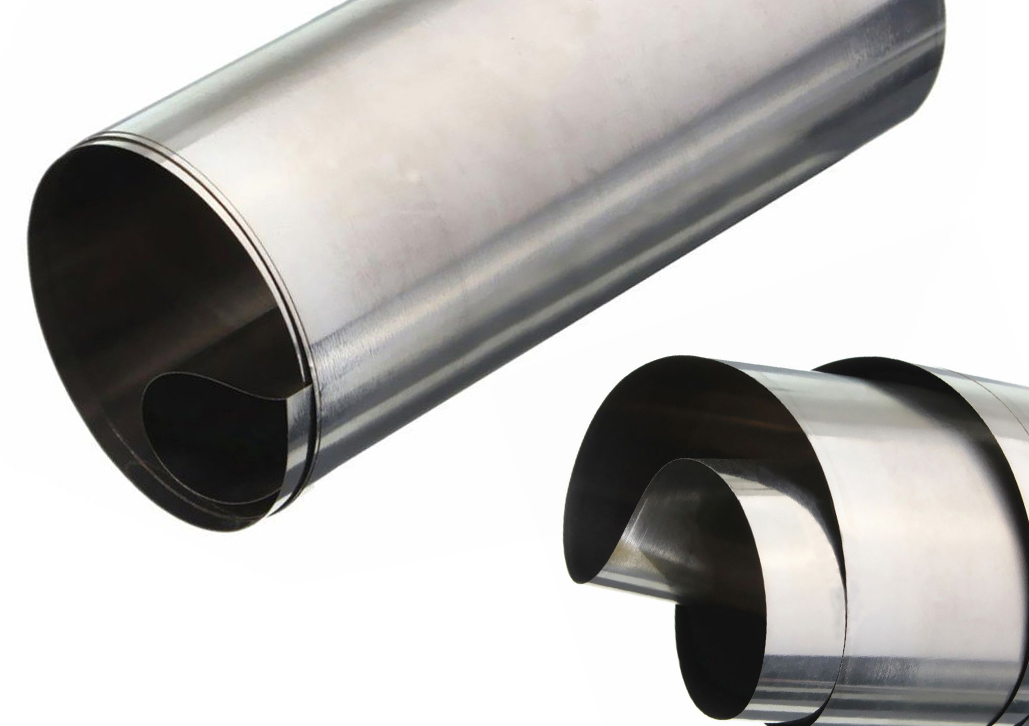

Foils

Metal foils are extremely thin sheets of metal, often below 0.2 mm in thickness, used in applications that require flexibility, high conductivity, and precision. Foils are widely used in electronics, aerospace, automotive, packaging, insulation, and medical industries. They are available in a variety of materials including stainless steel, copper, aluminum, and nickel alloys, and can be supplied in coils or cut-to-length forms.

Key Features

- Ultra-thin profiles with thickness typically below 0.2 mm.

- Available in annealed, hard, and coated conditions.

- Offered in stainless steel, aluminum, copper, and nickel alloys.

- High formability and corrosion resistance for demanding applications.

- Used in insulation, electronics, battery components, packaging, and shielding.

Applications of Sheets & Plates

Sheets and plates play a crucial role in various industries due to their strength, corrosion resistance, and adaptability. Some of the key applications include:

- Oil & Gas Industry: Used in offshore platforms, refineries, and storage tanks for corrosion-resistant structures.

- Petrochemical & Chemical Industry: Essential for manufacturing reactors, heat exchangers, and storage vessels for hazardous chemicals.

- Power Plants: Used in boiler components, turbines, and pressure vessels in thermal, nuclear, and hydroelectric power plants.

- Water Treatment & Desalination: Applied in tanks, filters, and pipelines for water purification and wastewater treatment plants.

- Pharmaceutical Industry: Used for cleanroom walls, sterile processing equipment, and medical storage tanks.

- Food & Beverage Industry: Stainless steel sheets ensure hygienic surfaces in food processing, brewing, and dairy industries.

- Marine & Shipbuilding: Used for hull structures, deck plates, and corrosion-resistant marine components.

- Construction & Infrastructure: Integral for roofing, cladding, bridges, and high-rise building structures.